Toyo Ink SC Holdings, the mother or father firm of specialty chemical compounds agency Toyo Ink Group, has developed a silver nanoparticle paste for die-attach purposes. This lead-free materials is engineered to fulfill the wants of next-generation energy electronics, able to sintering at low temperatures beneath each pressureless and pressure-assisted strategies.

The silver nanoparticle paste, born from the corporate’s Corporate R&D Division, caters to the rising demand for higher warmth resistance and warmth dissipation in electrical interconnects. The paste is right for silicon carbide (SiC) units and different superior energy electronics. With bond strengths of 40 MPa and above, the paste ensures the sustainable, high-temperature operations of high-power semiconductors utilized in electrical automobiles, radio frequency (RF) transistors, and light-emitting diodes (LEDs).

The international shift towards package deal miniaturization, bigger wafer sizes, and elevated switching frequencies and energy densities has spurred the demand for energy semiconductors with strong warmth resistance and warmth dissipation. Traditional tin- or resin-based electrical interconnections have been discovered missing, unable to fulfill the necessities of high-power units as a consequence of their poor electrical and thermal conductivities. Toyo Ink’s reply to this industry-wide problem is their silver paste die-attach answer.

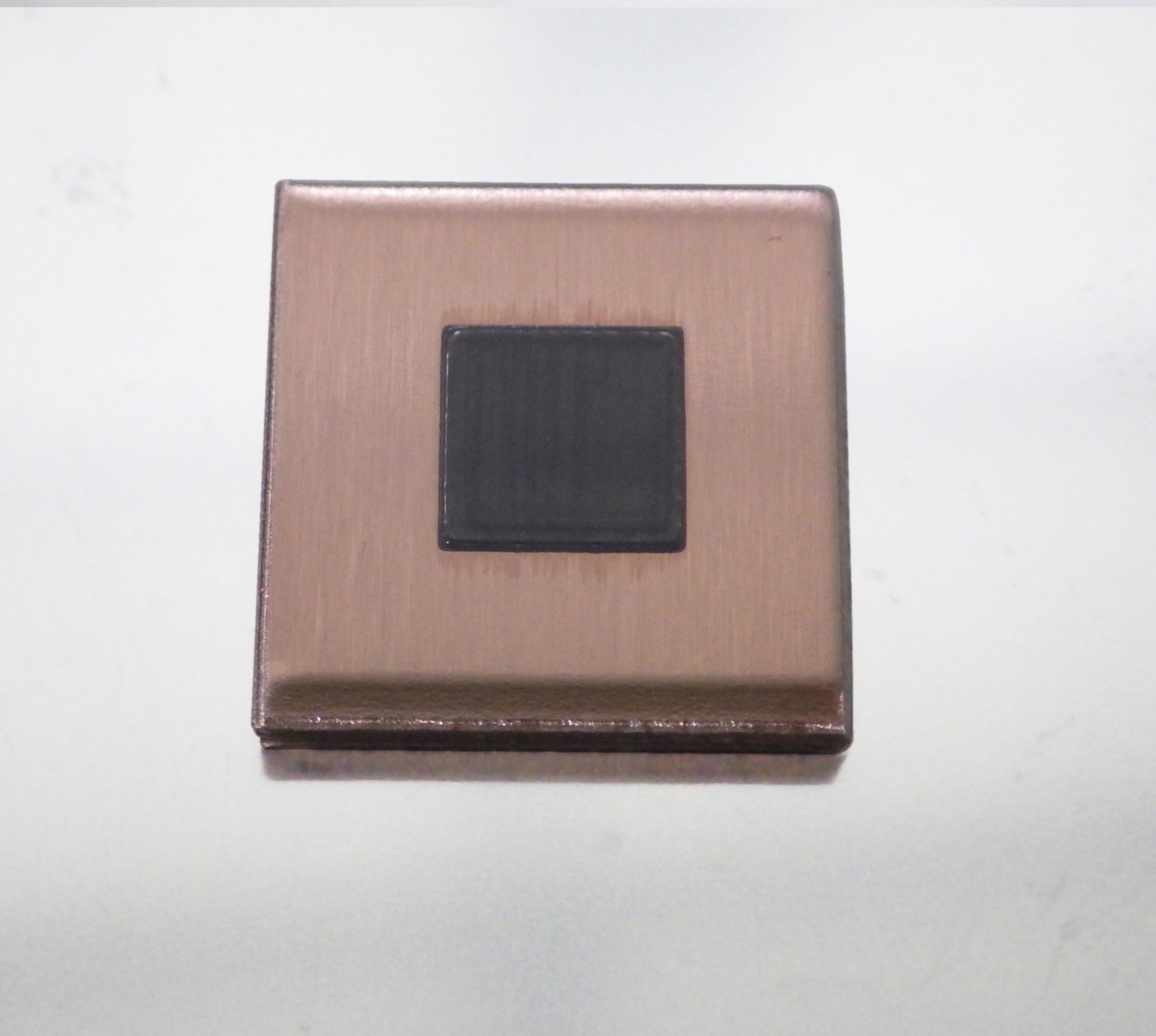

Masashi Arishima, division director of the Corporate R&D Division at Toyo Ink SC Holdings, shared the corporate’s anticipation over the silver sintering paste’s introduction to the worldwide market. “We utilized our proprietary nanoparticle and paste design technologies to control the density of sintered films applied onto copper substrates,” Arishima defined. “This process resulted in bonding layers with uniform densities and no large voids in the sintered structure.”

Arishima additionally famous that in trials with automotive digital units, the paste demonstrated superior bonding when distributed at decrease temperatures between 230 and 300 levels Celsius, beneath each pressureless and pressure-assisted programs. The sintered silver joints exhibited excessive thermal conductivity exceeding 300 W/m-k.

“Based on these findings, we are confident that our advanced silver pastes can meet the performance and longevity standards required by the high-temperature, high-power applications of today,” Arishima stated in conclusion.